|

Magnetometer

Running Total Hours:

0.0

| 2009.05.19: (0.0)

The magnetometer is a solid state device that can measure the magnetic

field in three dimensions, and is a key component of any EFIS

system. It is obviously used in determining the aircraft's

heading, but may also be used by the AHRS as an aiding input to the

attitude solution. While some EFIS systems may incorporate the

magnetometer in the main box, most EFIS systems today (including AFS,

Dynon, GRT, BMA) use a remote magnetometer module, such that it can be

mounted in another location that is sufficiently free of magnetic

interference, unlike the instrument panel. The magnetometer also

has to be mounted in the same orientation as the AHRS, in all three

axes, within fairly tight tolerances. [Theoretically, the

magnetometer could be mounted in any orientation, as long as the

orientation relative to the AHRS is known, and can therefore be

corrected for numerically. But most EFIS vendors don't seem to

support that option.]

I'm currently planning on an EFIS from Advanced

Flight Systems, so details of the magnetometer installation that

are vendor-specific are based on Advanced Flight Systems'

requirements.

MAGNETOMETER LOCATION

The number of suitable locations for the magnetometer are actually

fairly limited due to the need for it to be free of magnetic

interference. AFS generally recommends that the magnetometer be

located at least 24 inches away from any ferrous object, any moving

metal object (ferrous or not), and any wires carrying any significant

current. Most other EFIS vendors have similar recommendations.

There is actually no location on the RV-7A that strictly meets that

criteria. But the most suitable location, and one that has

seemingly worked well for others, is on the top forward side of the

F-707 bulkhead (one bay aft of the baggage compartment). At this

location, the magnetometer is sufficiently far away from the elevator

bellcrank and pushrods, autopilot pitch servo, steel rudder cables,

the wire harness running along the bottom to the aft fuselage, and the

baggage compartment (who knows what someone might put there???).

However, it is only about 8 inches away from the steel cables that

secure the pilot and passenger shoulder harnesses to the longerons in

the aft fuselage. These are

ferrous (steel), and worse, they can move around somewhat when they are

slack. But the good news is that we can easily test and find

that they have little effect. Measuring with a mechanical

compass as well as with a digital compass (both mountaineering equipment) I

see less than ±1° of deviation with the cable 8 inches away from the

compass. But there is definitely an effect. At 1 to 2

inches away, the cable will cause the compass to swing as much as

5°. And the clevises at the ends of the cable can swing the

compass a full 90°, but fortunately these will always be far from the

magnetometers. Still, I may experiment and see if I can degauss

the cables to get rid of as much magnetic bias as possible.

MAGNETOMETER MOUNT

So I've picked the location, but there are still some challenges to

mounting the magnetometer. It has to be aligned with the AHRS in

all three axes within 0.2° (sounds like people are actually getting

away with much looser tolerances, but 0.2° is what AFS specifies and

that's what I intend to meet). In the AFS EFIS, the AHRS is inside the main box

that goes in the instrument panel. And in the RV-7A, the

instument panel is not perfectly vertical but rather tilted forward about

7.7° in pitch. So the magnetometer mount must be tilted in pitch by the

same amount. The other two axes should match those of the

airplane. With careful measurements and a digital level, I think

I can meet the 0.2° spec.

The tricky part here is that there is no really good structure to

attach a mount to. The F-707 bulkhead itself would be the

obvious choice, but the way it's put together, it's actually not so

great. It is a relatively floppy structure with easily a few

degrees worth of flex. Even just sitting there now, it naturally

deviates away from its proper plane (partly due to its flimsy design,

partly due to less than exacting workmanship by the QB factory).

And the bulkhead has a stiffener bead protruding forward, getting in

the way of attaching any flat flange to the forward side of the

web. Just plain unfriendly.

Also complicating matters, I want to make provisions for mounting two

magnetometers. To minimize interference, they should also be

spaced apart from each other as much as possible. Rob Hickman at

AFS has found in his RV-10 that about 10 inches apart is sufficient,

so that's about what I'm shooting for.

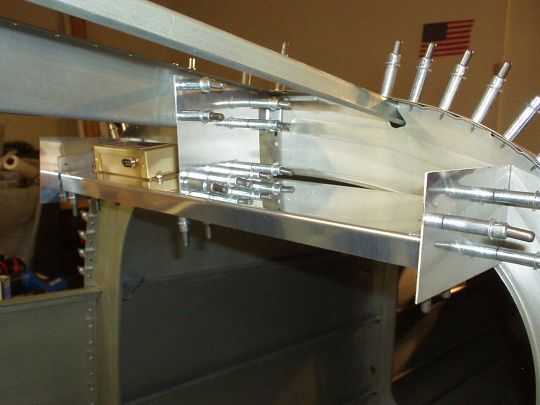

I sketched out a few different designs for the mount, and here's what I

finally settled on. The mount will be an 18 inch wide tray, with

three brackets attaching it to the fuselage. One bracket in the

center attaching it to the F-787 stringer, and one bracket on each

side attaching it to the F-707 bulkhead. The center attachment

to the stringer provides a very stable reference for the pitch

axis. The side attachments to the bulkhead provide a

stable reference for the other two axes due to the 18 inch distance

between them. The tray itself will have 90° flanges to make it

very stiff longitudinally. It'll still be able to twist a little

with the bulkhead, which I think to a degree is actually desireable, so that

the mount doesn't induce excessive stresses on the bulkhead as the

aircraft twists under load. Any twist

under normal conditions should be negligible for the orientation of

the magnetometers. |

| 2009.06.27: (0.0)

I've received the Advanced

Flight Systems magnetometer (AFS p/n 8350-0480) from SteinAir.

Note that this magnetometer is actually made by Crossbow,

and carries a Crossbow label specifying "Model: CRM300CA-100,

Part No: 8350-0480-03, Serial No: 0901000362".

My fabrication of the mount is well under way. Its main

structure is fitted in place, and only some final trimming

remains. I drilled mounting holes for two magnetometers, spaced

laterally approximately 11.25 inches apart center-to-center.

[Note that the attachment hardware shown in the following photos is

stainless steel, but this is just temporary. Non-ferrous

hardware will be used in the final installation.]

Note that Dynon's magnetometer, incidentally, has exactly the same

footprint as AFS's, so my mount as-is will accomodate either.

And while I'm at it, I may drill mounting holes for other

manufacturers' magnetometers as well, since it's easy to do at this

stage. |

| 2009.07.07: (0.0)

As I expected, this mounting tray design still has a little bit of

freedom to twist, i.e. the left side can pitch up a little while the

right side pitches down a little, or vice versa. Not a lot, but

enough that I was a bit worried about it flexing unevenly under heavy

G-loads (since it's asymmetric), or resonating with normal vibration

of the airframe. So I decided to stiffen it up by adding a

member from the forward left corner of the tray to the

bulkhead-longeron intersection underneath, thereby creating an

excellent truss. Sure enough, this stiffened it right up.

I'm not doing the same on the right side because 1. it is unnecessary,

and 2. again, I want to leave enough flexibility so that it doesn't

impose any hard stresses on the bulkhead as the airframe naturally

flexes and twists. [An alternate design could have had trusses

on both sides and eliminated the center support. That would

probably work reasonably well. But the center support is still a

stiffer reference for pitch angle, and it also made it much easier to

set pitch angle first, without worrying about other two axes, so it

made for a more manageable construction sequence.]

I did the final trimming, removing excess material, rounding over

corners, etc. And treated all the parts with alodine, followed

by AKZO primer. Now all that remains is to rivet it, but I'll

wait on that for now so it's not in my way. |

| 2011.04.21: (0.0)

Installed. The top skin is riveted, as is the magnetometer

shelf, and the magnetometer is mounted in its place. Note that

to secure the magnetometer to the shelf I used mounting hardware (#6

screws, nuts, washers) made of aluminum, for magnetic

considerations. I found this aluminum hardware at Marshalls (not

cheap of course...). Had to shorten the screws. And also

gave all the hardware an alodine treatment for good measure. And

finally, used some loctite to make sure everything stays put.

|

|

|