|

Empennage Fiberglass Tips & Fairings

Running Total Hours:

0.0

| 2007.04.17:

(10.0) Trimmed and

fitted the rudder bottom fairing. The fairing as it arrives from

Van's is composed of two molded halves that have already been

joined. Unfortunately, the weren't joined quite symmetrically,

and had some definite twist. It was close enough to be usable,

but just wasn't pretty if you sight it down very closely. Having

resigned to pick my battles with Van's, I decided to use it anyway and

make the best of it by trimming such as to balance the twist fore and

aft as much as possible. I also found that the forward end fit

better inside the flanges of the rudder's spar than outside. So

be it.

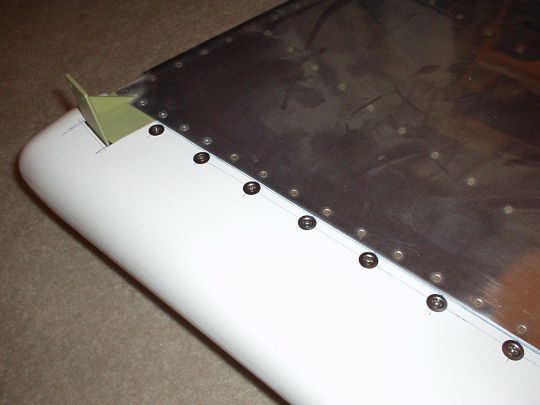

The rudder bottom fairing attaches to the rudder from the

outside. Or in other words, the aluminum flanges of the rudder

go behind the fiberglass. I decided to fasten the fairing to the

rudder using platenuts and MS24693C2? #6 stainless steel sountersunk

screws. To better protect the fiberglass from the head of the

screw, I'm also using countersunk finishing washers to spread the

load. I will likely use the same method to fasten other fairings

that attach from the outside.

It seems that MS24693C screws are not so easy to find in certain

sizes. But between Aircraft Spruce and McMaster-Carr I was able

to get a good assortment. The stainless steel countersunk

finishing washers also came from Aircraft Spruce (Spruce p/n 04-00397,

Mfg ??? p/n A3236-SS-012). |

| 2009.03.17:

(0.0) Working on the elevator

tips. I had already drilled them way back when I built the

elevators, but now there is still trimming to be done, and ultimately

some kind of closure around the front where the lead weights are

located. For now, I just cut the clearances around the front so

there's no interference with the lead weights. And I bonded in

some 0.020" aluminum backing strips to spread the pressure of the

pop rivets that will hold the tips in place. |

| 2009.04.06:

(0.0) Working on the right

elevator tip. I filed down the lead counterweight around the

sides to remove interference with the fairing, and around the front to

match the curvature of the aluminum inboard of it, plus a few mils

deeper to leave room for fiberglass. I laid up fiberglass (one

ply of RA7781) all around the part of the lead counterweight that

resides inside the fairing. I figured that doing this would give

me the best possible adhesion over the largest possible surface area

of the lead, and then provide a better bonding surface (fiberglass

rather than lead) for the final installation of the fairing.

[these photos actually show the left elevator, which I did later]

I

also laid up another layer of glass on the inside of the fairing for

about 2" from the forward end to reinforce it (these molded parts

from Van's are pretty crappy, and this one had massive voids and

cracks in that area, which I fixed as well as I could). With

this added glass there was still a millimeter or two of clearance

between the fairing and the lead weight. I installed the

fairing, using flox to fill that clearance.

I also used flox to

bond the fairing along its length to supplement the pop-rivets and

fill the seam. Since the lead counterweight design forced me to

bond the fairing in that area, making it a "permanent"

installation, I figured I may as well bond the rest of it too and make

it as strong as possible. After this all cures, I'll sand down

the forward end to a nice contour, and add a ply of glass to seal the

deal.

Side note: For my next RV (just kidding!) I would consider another

approach, and make the elevator tips removeable. Van's sure

didn't make that easy with the molded counterweight design, but by

trimming back the counterweight even further, and capping the fairing

around the front, it could be done. That would make it possible

to adjust the counterweight without drilling holes into it from the

outside ("sub-optimal", to put it nicely), and would also

eliminate the need to bond composites to metal (also

"sub-optimal").

Working on the left elevator tip, same technique, just a few steps

behind. And I also started fitting the HS tips. |

| 2009.04.16:

(0.0) Elevator tips are now

bonded closed, but more shaping and possibly some glassing will be

required at the forward ends.

Started working on the HS tips. Matched drilled the tips to the

HS, and trimmed them to achieve the minimum 1/8" gap from the

elevator counterweights. Bonded 0.020" aluminum strips on

the inside to reinforce the rivet line. I decided to cap the aft

end of the HS tips, and my technique of choice was to form an end rib

and then bond it in place. I fabricated the end rib by making a

balsa core (2 plies of 1/8" balsa bonded together with their

grains at 90° to each other), and then laying up fiberglass to

encapsulate them all around. The fiberglass along the edges then

provides a good surface for bonding into the tip using flox.

|

| 2009.05.28:

(0.0) I permanently installed

the HS tips using CS4-4 pop rivets and epoxy/flox.

I fitted the top rudder tip. This one was a bit of a challenge

because it was molded complete at the factory, including the forward

end cap, but was about 3/16" too short for a good fit. Argh

@#%$!!! I know this is a common problem because I've seen

completed RV's where the builder just attached the tip with this

grossly poor fit (very noticeable!). Anyway, I decided to fix

this by building up material to extend the forward end cap. This

approach will add just a bit of extra weight, but it's actually in the

ideal location to aid in counterbalancing the rudder, so I'll take

it. I did this by prepping the surface of the forward end cap,

taping a "dam" of 4 mil plastic sheeting to extend the

contour of the fairing as an ad-hoc female mold, and then pouring in

flox about 1/4" deep. I should elaborate just a bit further

on the flox. I actually poured it in in several stages, starting

with neat epoxy and moving gradually to increasingly thick

mixtures. I did this to ensure that I didn't get any voids

around the sides where a viscous mixture would have a hard time

penetrating.

After it cured, I then shaped the flox using abrasives and files,

first the bottom part to fit into the rudder counterbalance arm, and

then the top part to match the exterior contours.

Note also that I elected to make the rudder top tip removable using

screws and nutplates rather than to permanently install it. I

made this decision early on when I built the rudder, the reason being

to provide access to add counterbalance weight if necessary using a

couple of extra nutplates that I installed on the top of the

counterbalance arm. Not sure if this will be necessary or

not. I'm told that rudder doesn't need to be quite neutrally

balanced. But anyway, the provision is there.

Finally, I fitted the VS tip using the same methods I used for the HS

tips.

All that remains now is a bit of sanding to shape the forward end caps

of the elevators and rudder, and surface finishing, i.e. fill, sand,

fill, sand... on all the emp tips. I'll put that off for

now. I need a break from composites work. |

| 2010.11.14:

(0.0) Fitting the empennage

fairing... Like most of the fiberglass components in the kit, it

fits just well enough to make me not want to throw it away and start

from scratch, but poorly enough that it'll take a week or two to

massage it into a good fit. I'm now a few days into that

drudgery, but it's starting to shape up.

I'm also making some mods in the attachment of the bottom gap

fairing. In the plans, this aluminum strip is attached to the

fuselage using #6 screws (into tapped holes in the longeron) and a

rubber channel closes the gap between the top of the strip and the

bottom skin of the HS. Several details of this attachment are

clunky at best. Given that, and the fact that there is no good

reason for the bottom gap fairing to be removable, I've decided to

simply rivet it to the fuselage, and use proseal to fillet the

intersection between the top of the gap strip and the bottom of the

HS. Not done yet, but that's the plan.

I just noticed that I hadn't taken any pictures of the installed HS

and VS tips (done last year), so here are some pics:

|

|

|