|

Angle of Attack (AoA) Instrument

Running Total Hours:

0.0

| 2009.07.17: (0.0)

Some background: Angle of attack (AoA) instruments are still uncommon

in small general aviation aircraft, but have been in use for decades

on higher performance and especially naval aircraft. Having a

true AoA indication allows the pilot to fly the airplane much more

precisely at high angles of attack than he could by using airspeed as

an approximation. With the AoA instrument the pilot can

consistently pin-point L/D-max, the critical angle (i.e. stall angle),

or any other desired AoA irrespective of gross weight, G load, or

airspeed. This is especially useful in pin-pointing best rate of

climb (Vy), best glide (Vg), max endurance cruise, preventing stalls

in all flight regimes, and flying consistent approaches (all carrier

approaches are flown at fixed AoA, not airspeed).

PSS / AFS AOA INSTRUMENT

So, my airplane will have an AoA instrument. The one I chose was

originally designed by Jim Frantz of Proprietary Software Systems,

Inc. and sold in two variants as a stand-alone product. In 2004

Advanced Flight Systems bought the rights, and has integrated it as an

option to their EFIS products (they also continue to sell the original

stand-alone products). This particular AoA instrument is unique

in that it doesn't require any external veins or probes. It uses

two tiny holes in the wing, one on the top and one on the bottom at

the same percent chord, to measure differential pressure. Dividing

this by the pitot-static differential pressure yields a coefficient of

pressure that varies linearly with angle of attack. The product

documentation is excellent, and explains the theory of operation in

great detail. [Note: one disadvantage of this system is that it

also relies on pitot-static data, and therefore does not serve as an

independent backup for the airspeed indicator, but I can live with

that.]

I'm holding off on the major avionics purchases for now, but still

trying to fit all the remote sensors so I can close up the airframe

structures, in this case the wing. Fortunately, AFS sells their

AoA option in two pieces: the "A kit" containing the

pressure ports and plumbing, and the "B kit" being the

corresponding hardware/software option in the main EFIS box (the

"A kit" is the same for the EFIS-integrated option or for

either of the stand-alone variants). So for now I purchased the

A kit through Stein, and that will enable me to finish up the wings.

PRESSURE PORT INSTALLATION

I decided to install the pressure ports in the left wing, for no

particularly strong reason. Aerodynamically, they could go just

as well in either wing, but I opted for the more direct routing of the

pressure lines to the pilot-side main EFIS box.

The exact location of the ports is per the manufacturer's

recommendation specific for the RV-4/6/7/8. These have been

tested on several aircraft, have been shown to work well, and the

corresponding calibration data is available. The ports are

located in the outer-most wing bay, 6 inches forward of the wing skin

break at the spar (approx 12 inches aft of the leading edge).

Span-wise, the upper port is located 4.75 inches inboard of the edge

of the skin, and the lower port 7.5 inches inboard of the edge of the

skin. Note that I was concerned initially that this location is

behind the duckworks landing light, and the interface between the lens

and skin may interrupt the airflow and affect the pressure at the

ports. However, Rob Hickman of AFS had noted on the AFS support

forum that this has been tested and shown not to be an issue. He

noted that in fact the default calibration data was obtained from

Jerry VanGrunsven's RV-6 that had the landing lights in front of the

AoA ports.

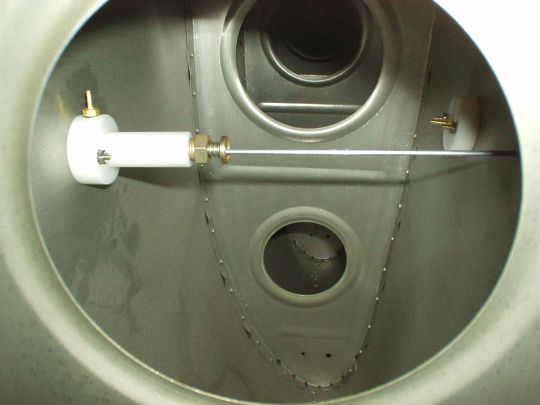

The pressure ports are each implemented with a piece of machined

delrin that attaches to the inside of the skin with two countersunk

#4-40 screws and nuts (and will be pressure sealed with a gasketing

material on final installation). Note that the #4-40 screws

provided with the kit don't appear to be standard mil-spec hardware,

and I'm uncertain of their exact countersink angle. I replaced

them with MS24693-S8 screws that have a 100° countersink angle, and

conveniently very close to the same head dimensions as an 1/8 inch

diameter AN426 rivet. Still, the diameter of a #4-40 screw shank

is

considerably smaller than 1/8 inch, but that's no problem. I

found a good way to drill and dimple the wing skin for these

screws. Drill the holes to #34. A #4-40 screw will just

barely slip through that hole, and so the delrin part can be screwed

into the first hole and then used as a guide for precisely positioning

the second hole. After both holes are drilled, they are dimpled

using a pair of dimple dies that are pulled with a pop-rivet puller

tool (not to be confused with 120° pop rivet dimple dies, these are

100° dimple dies meant for solid 1/8" rivets). These

1/8" solid rivet 100° dimple dies are available for about $10

from Wicks. The nails that are provided with the dimple dies for

use as a puller shank are actually quite smaller than 1/8" and

fit easily through a #34 hole. The dimpling process enlarges the

hole slightly so a #4-40 screw now slides through it easily, and the

dimples fit the MS screw heads quite nicely.

The actual pressure taps are drilled with a #60 bit. The tiny

hole size is reportedly sufficient, and effective in keeping the bugs

out and even the rain.

Still, the upper pressure port has potential for water infiltration,

so the delrin part is designed as an air-water separator, essentially

a water trap beneath the air pressure nipple. The water trap has

a spring-loaded drain (like those used on fuel sumps), but it is

located inside the wing to keep the installation simple and minimize

added drag. The drain is accessed by poking a stick through

another small hole drilled in the bottom wing skin. The poker

(provided) is 0.092" thick, and I drilled the hole to #40.

Note that the hole is obviously at the same span-wise position as the

upper port, but is about 3/16" further aft than the chord-wise

position of the ports. That is to place on-axis with the upper

port, considering that the upper and lower wing skins are not in

parallel planes to each other.

|

|

|